Processing

- BTP Mechanics

- Processing

Lavorazioni

Materials Processed

After conducting an initial inspection of the drawing delivered by the Customer, B.T.P. Meccanica Srl selects the raw materials to be used for machining mechanical parts and is responsible for sourcing them. Choosing qualified suppliers enables this company to. To keep the quality standard of the products made adequate and high.

Acciaio comune da costruzione C45

Acciai destinati al trattamento di bonifica (tempra seguita da rinvenimento intorno ai 600°) che attribuisce all’acciaio resistenza e tenacia. Vengono impiegati nel settore meccanico per la costruzione e la lavorazione di particolari meccanici sottoposti a sforzo quali ingranaggi, manovelle, supporti, aste, perni, semiassi mazzi e alberi.

Acciaio comune da costruzione C45

Acciai destinati al trattamento di bonifica (tempra seguita da rinvenimento intorno ai 600°) che attribuisce all’acciaio resistenza e tenacia. Vengono impiegati nel settore meccanico per la costruzione e la lavorazione di particolari meccanici sottoposti a sforzo quali ingranaggi, manovelle, supporti, aste, perni, semiassi mazzi e alberi.

Acciaio 39NiCrMo3 (38NCD4)

Tipologia di acciaio legato usato nella costruzione di organi meccanici soggetti a sollecitazioni e torsioni come alberi, tiranti, ingranaggi, portastampi sollecitati e stampi integrali.

Acciaio 39NiCrMo3 (38NCD4)

Tipologia di acciaio legato usato nella costruzione di organi meccanici soggetti a sollecitazioni e torsioni come alberi, tiranti, ingranaggi, portastampi sollecitati e stampi integrali.

Acciai speciali da costruzione

Acciai speciali che comprendono una serie di materiali che vengono messi in opera dopo opportuni trattamenti termici o termomeccanici tali da esaltarne le proprietà. Sono destinati a diversi utilizzi nel settore metalmeccanico.

- Vengono eseguite lavorazioni di varie leghe in alluminio dalla diversa resistenza meccanica a trazione.

Acciai speciali da costruzione

Acciai speciali che comprendono una serie di materiali che vengono messi in opera dopo opportuni trattamenti termici o termomeccanici tali da esaltarne le proprietà. Sono destinati a diversi utilizzi nel settore metalmeccanico.

- Vengono eseguite lavorazioni di varie leghe in alluminio dalla diversa resistenza meccanica a trazione.

Processo produttivo

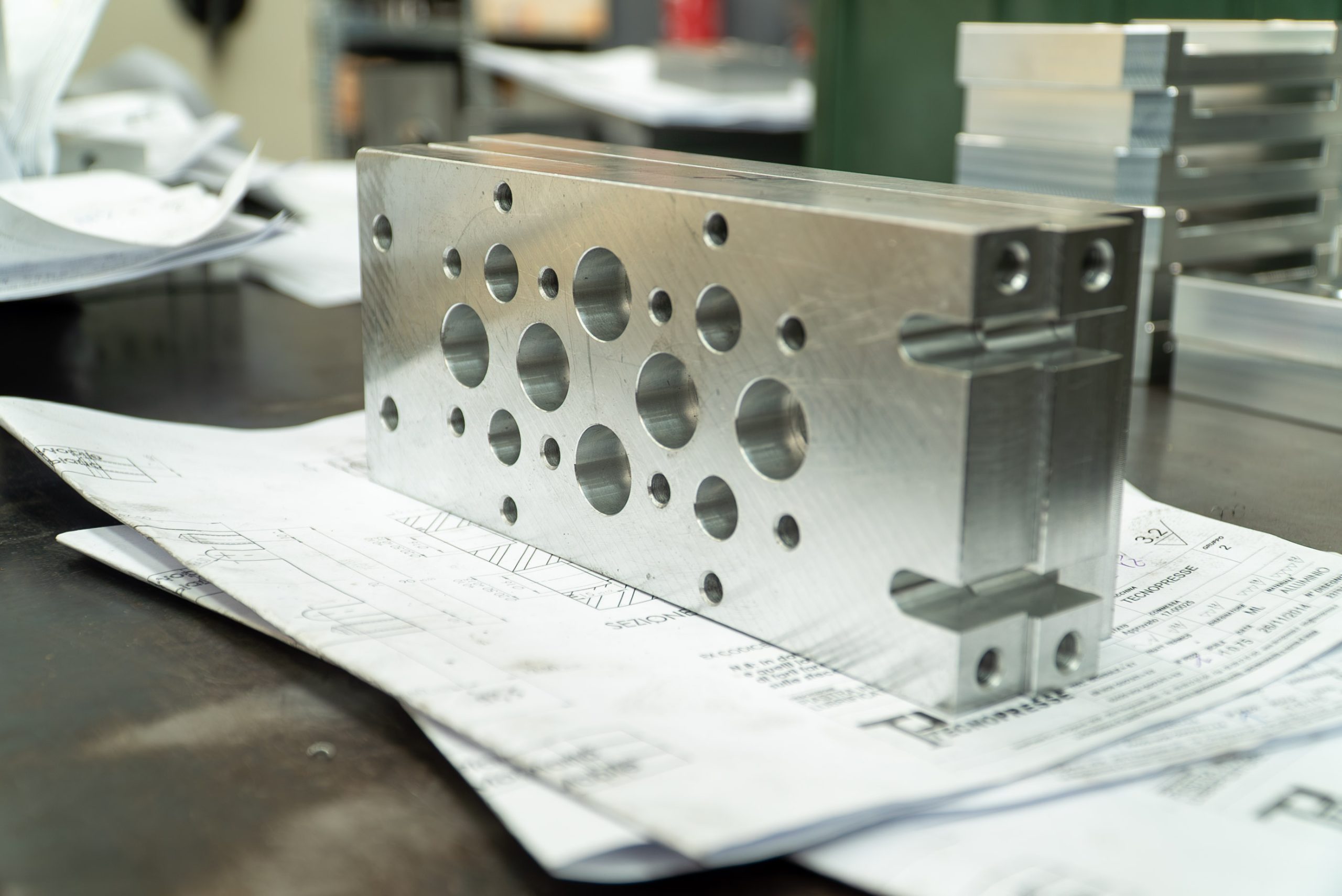

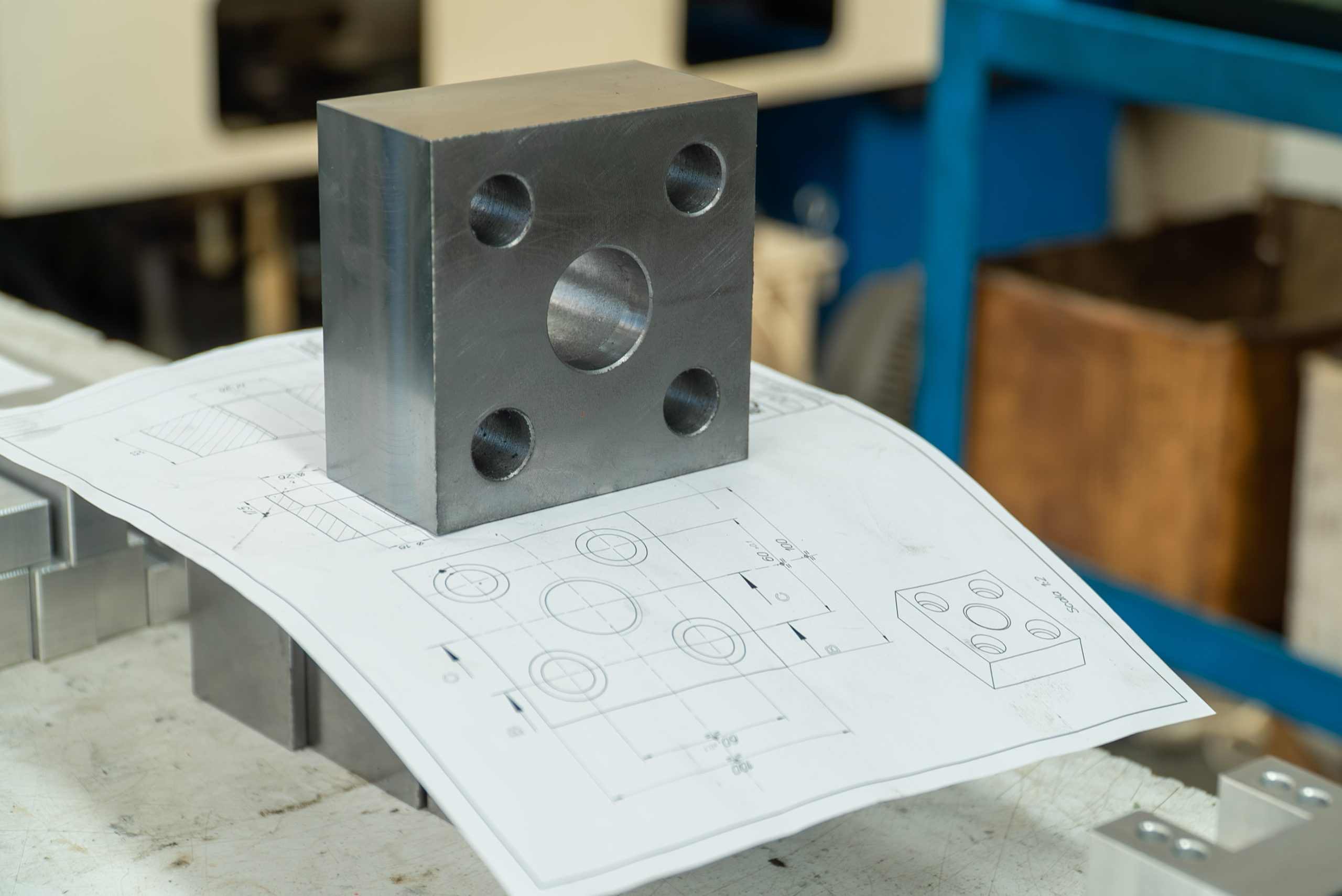

First-rate aluminum and steel processing

B.T.P. Meccanica Srl performs machining on aluminum and steel of various types, including turning, milling and boring for the construction of equipment, mechanical parts for transfer machines and for contract assembly machines.

The trained and knowledgeable staff performs specific mechanical machining (on aluminum and steel) starting from knowledge of the technical drawing through machine tooling and programming; fundamental requirements to ensure a result that fully meets the Client’s needs. For this reason, BTP Meccanica is also the ideal partner for the production of custom parts.

Passion for work and traditional craftsmanship blended with technology and state-of-the-art machinery in the company in order to make products that live up to expectations. In fact, flexibility and quality of the work performed are guaranteed by a large fleet of traditional and CNC machines capable of complying with turning, boring and milling operations on aluminum and steel.

Trattamenti superficiali

Processing and treatments for your products

BTP offers surface finishing treatments on metals in Brescia. These surface treatments can be applied to a variety of surfaces to achieve certain desired characteristics or properties, such as increased corrosion resistance or improved mechanical sealing.

Our range of surface treatment services in Brescia enables the customer to achieve the highest quality product.

Surface treatments on metals in Brescia offered by BTP Meccanica enable the customer to achieve superior performance and the highest product quality, thanks to the use of the most modern technology available in the field of surface treatments. Our metal surface finishing treatment services in Brescia are able to meet the highest quality standards required by industry.

Our range of surface treatments includes galvanizing, sandblasting, phosphating, anodizing, oxidation, copper coating, chrome plating and others. Each of these treatments offers unique benefits in terms of wear resistance, improved corrosion resistance, improved appearance, improved mechanical and electrical properties, and more.